How to Adjust Serial and Lot Tracking for Inventory in Sage 300 ERP

In this article, we take a look at how small and medium sized businesses track inventory with Sage 300 ERP (formerly Sage Accpac). Specifically, we will go through the process of adjust serial and lot tracking when there is a difference between inventory items on hand and those recorded in the system.

Inventory Control Systems for Small and Medium sized Businesses

Small and medium sized businesses more and more have come to use some kind of software inventory control system. In truth, the size of the business has little to do with the necessity of implementing an inventory control system. What does matter is the volume of items being purchased, shipped, received, tracked, and stored.

Companies that operate with a high volume of inventory turnover are wise to incorporate some type of electronic inventory tracking, whether the inventory is for manufacturing, finished products, or for distribution. The spread of ERP technology to the SMB market segment, like Sage 300 ERP (formerly Sage Accpac), has enabled businesses to rely on these systems’ inventory modules to track levels, locations, lots, changes, orders, and so much more.

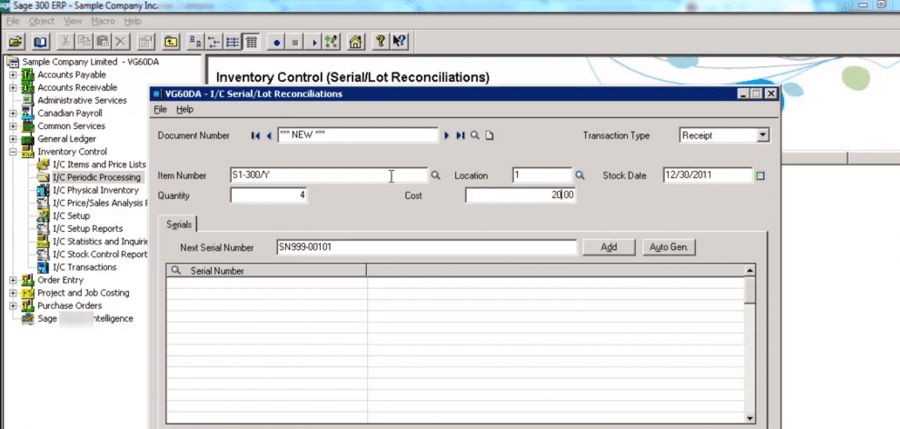

When items are received, shipped, or stored, the physical activities of handling inventory are virtually recorded within the system. Each item received is accounted for and given a serial number. Items are ordered and received in lots, generally of one pre-determined size.

For example, a company buying a product from a supplier will do so in lots of 100 units. All units in the lot will share some identifying characteristic, like being received on the same day or manufactured in a single production run. Each unit within the lot will then have its own serial number.

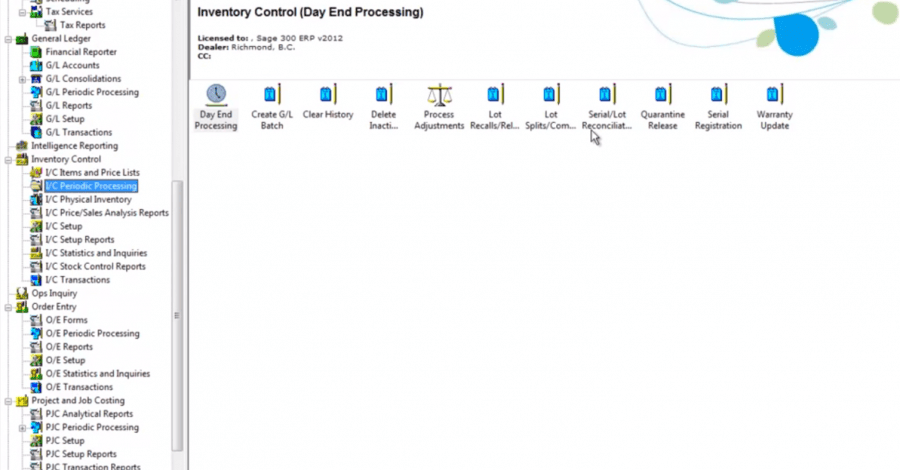

Adjusting Variance in Serial/Lot Tracking

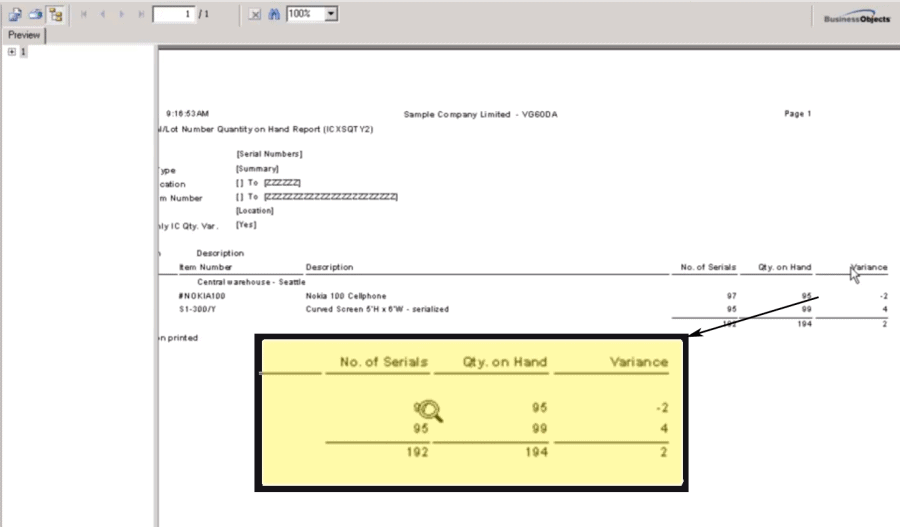

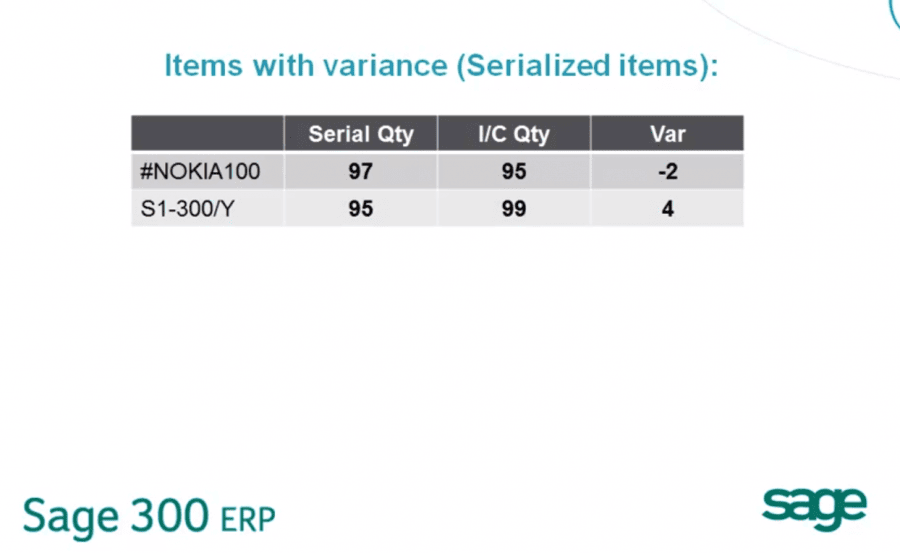

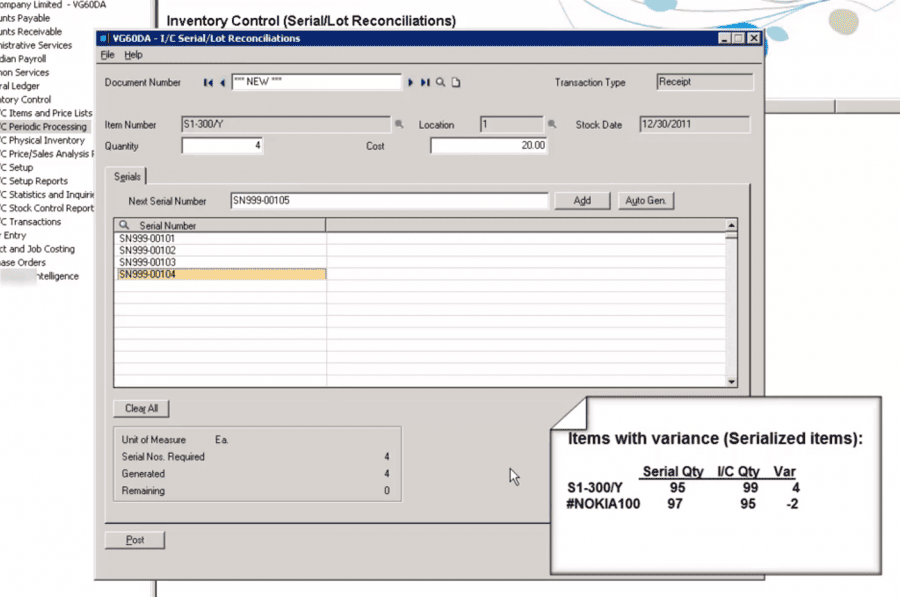

Companies usingSage 300 ERP (formerly Sage Accpac) may find that through the physical handling of inventory during receiving, usage, and storage, the numbers in the warehouse may not match the numbers in the system. This can happen at any time, but often it is noticed when companies do regularly scheduled inventory accounting. When that happens, there is a difference, or variance, in the quantities within lots in the systems, and in the serial numbers appointed the items.

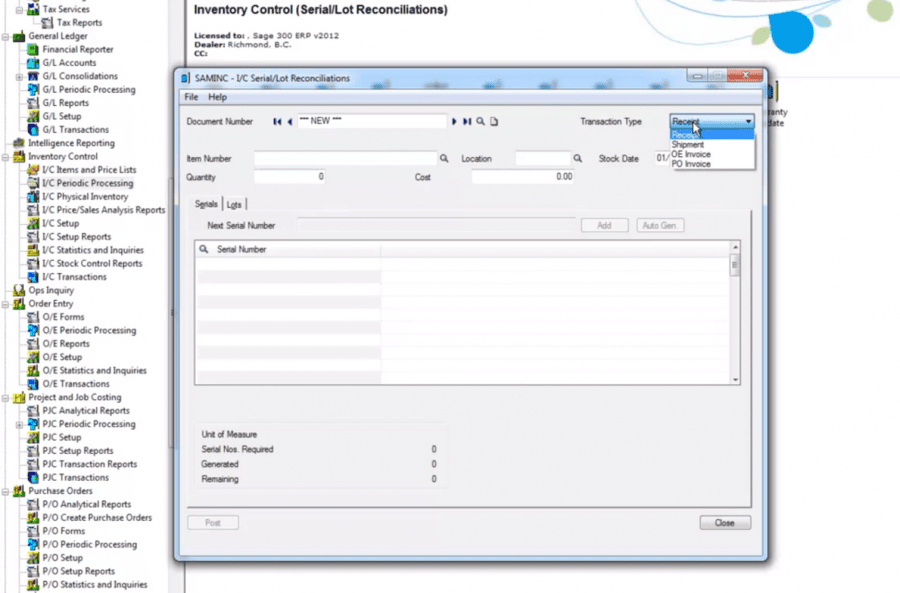

When this happens, it is very easy for users to fix and update serial and lot tracking to match the real status of items in inventory. It consists of two steps:

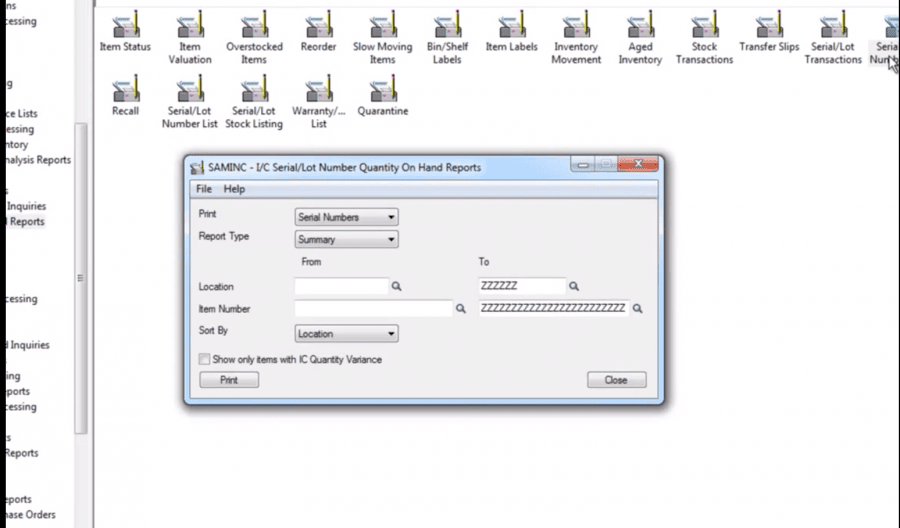

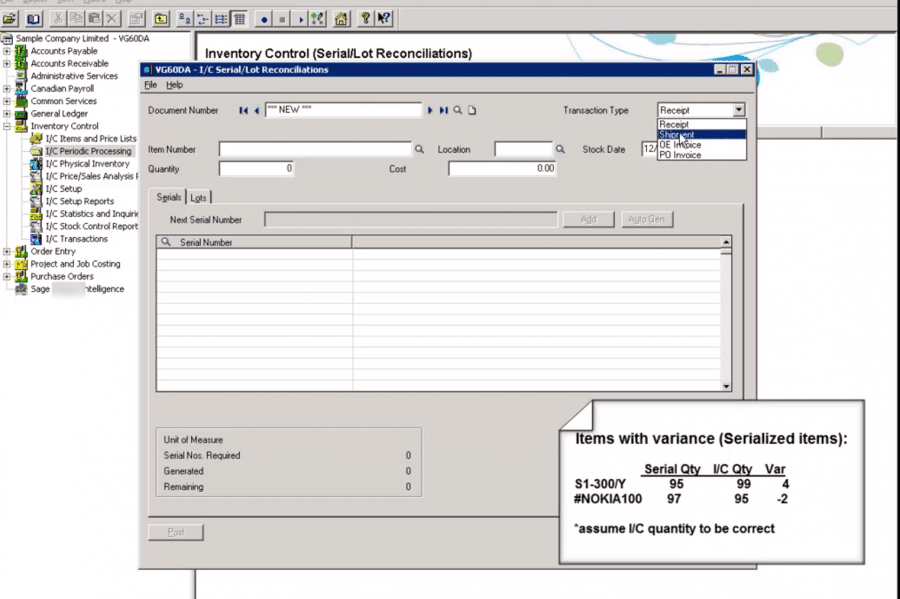

- Identifying the variance between serial/lot quantity and inventory at hand

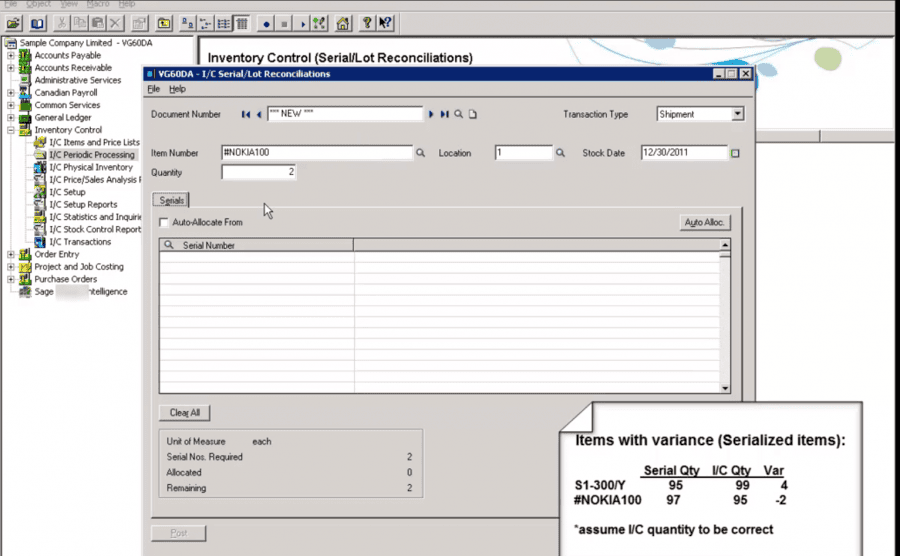

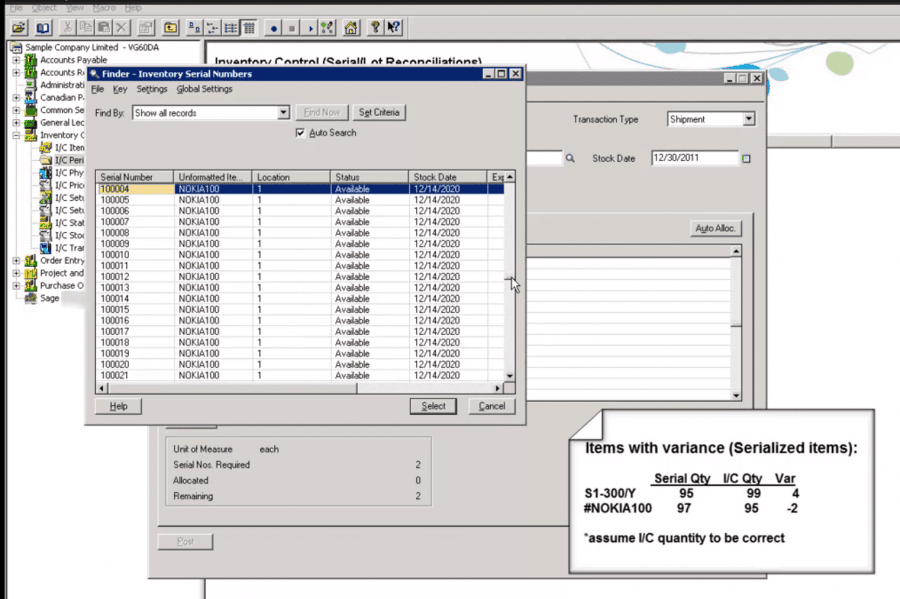

- Adjusting serial/lot quantity without affecting inventory on hand.

How to Check for Variance between Serial/Lot items versus actual inventory on hand

In a great tutorial video available at Sage City, the Sage 300 team explains how to do this procedure. We will cover the basic step-by-step here for serial items as well, and while the steps are mostly identical for lot number items, you should watch the video for details on that procedure. Note that for the exercises presented here, inventory on hand is assumed correct.

Adjusting Serial and Lot Items in Sage 300 ERP – Serialized Items with Positive Variance to Inventory on Hand

Adjusting Serial and Lot Items in Sage 300 ERP – Serialized Items with Negative Variance to Inventory on Hand

The same steps can be applied when dealing with lot numbers, by following the specific instructions related to quantities of items in each lot.

Whether you are a small business receiving 10 parts without access to have bar codes scanners or a large enterprise receiving hundreds of items, you will likely need to adjust inventory at some point. Hopefully this helps those adjusting variance in inventory. For more helpful tips you can contact us or visit the Sage City community website.